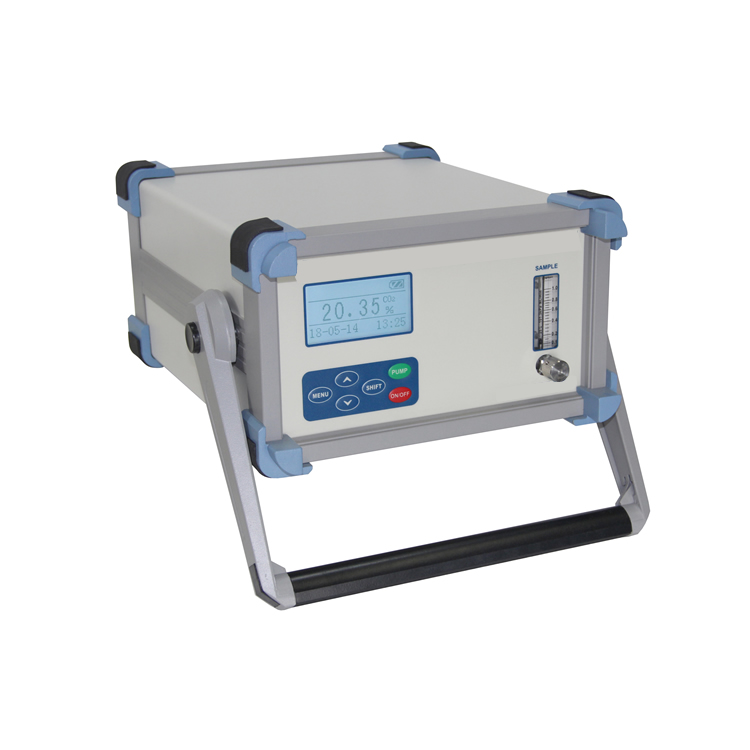

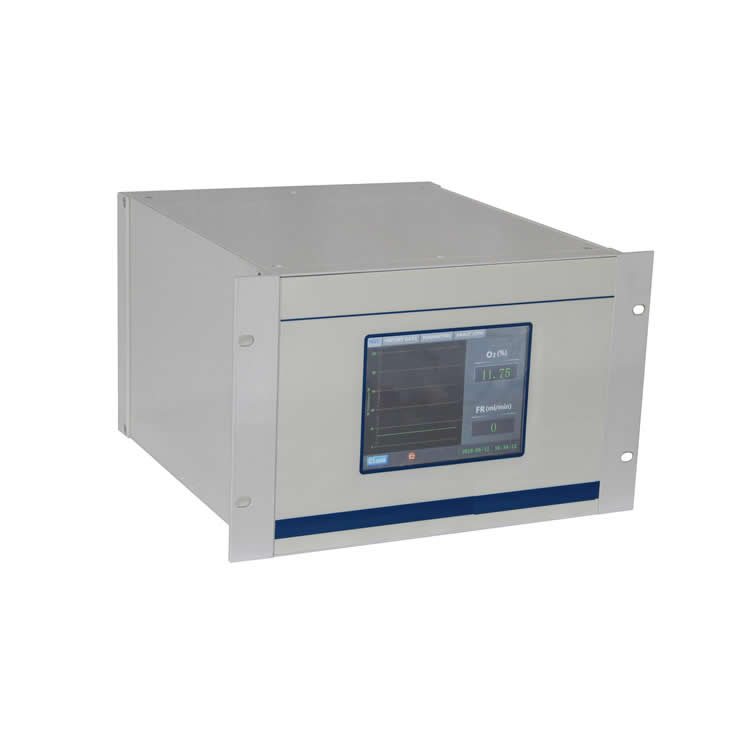

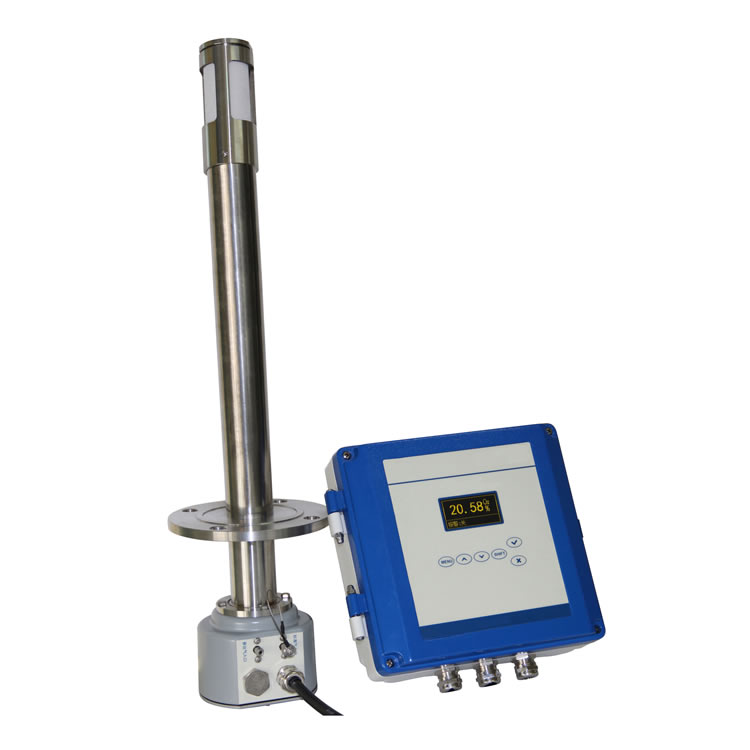

Online close-loop control oxygen analyzer has a friendly man-machine dialogue menu, which is intuitive and convenient to operate.It has a 320×240 dot matrix color LCD display, the display content is exquisite and clear. The imported zirconium dioxide sensor is with high measurement accuracy, a rapid response speed and long calibration cycle for features. The imported built-in sampling pump has long serving life and is reliable for working.

Online close-loop control oxygen analyzer main features:

1. The accurate measurement among the range of ppm ~ % can be met by one-point calibration in the air, making its calibration simple and convenient;

2. The sampling pump can be turned off automatically under the condition of gas circuit fault with the functions of gas circuit blocking alarm and self protection, which could extend the serving life of sampling pump and sensor efficiently;

3. Power being supplied at a wide range makes it more suitable for different occasions;

4. No reference gas is needed, and the analyzer wouldn’t be affected by the oxygen concentration of working around atmosphere;

5. Adopting RS232 (default) /RS485 (optional) bidirectional communication, it could do one-way or bidirectional communication with the upper computer;

6. The oxygen concentration in the gas protection furnace can be controlled automatically without manual control, making the response immediate;

7. The control error made by the pressure and temperature of the protection air source can be compensated automatically, making the components in the system more stable;

8. With the PID parameters self-setting function, users only need to do the self-setting operation, and the analyzer could calculate the optimal PID controlling parameter according to the relation between controlling output and oxygen concentration sampling input to accomplish the accurate and automatic control to the oxygen concentration;

9. It can save the protection air source at maximum, decreasing the maintenance cost efficiently;

10. Flow measurement function, with instantaneous flow collection and cumulative flow display, calculation, storage (storage once every 10 minutes) and clear (menu clear) function;

11. The meter is mainly used for nitrogen flow control of SMT main road. When the oxygen concentration in the core temperature zone is too low and the proportional valve dynamically adjusts the flow rate, the meter will automatically output a standard flow rate, so that the oxygen concentration in the furnace is always within the set range ;

12. With proportional valve inlet and outlet pressure detection function;

13. Bypass protection function, when the proportional valve fails, the bypass solenoid valve can be automatically opened in time to keep the shielding gas into the atmosphere protection furnace without manual intervention, and the response is timely and rapid, reducing the failure of the proportional valve. Loss;

14. The upper computer software is optional with the functions of curve display, data saving, parameters setting and so on.

Online close-loop control oxygen analyzer technical parameters:

Test principle | zirconium dioxide |

Display mode | 320×240 matrix dot color LCD |

Test Range | 0 ~ 10/100/1000ppm/ 1.00% / 25.00% O2 |

Accuracy | 0~1000ppm/1.00% / 10.00% / 25.00% ≤±1% FS 0~100ppm≤±2% FS 0~10ppm≤±5%FS |

Resolution | 0.1ppm |

Repeatability | ±1%FS |

Response time | T90≤60S |

Analog output | 4~20mA.DC(non-isolated output, loaded resistance lower than 500 Ohm) 0~10V.DC(non-isolated output, loaded resistance higher than 10k Ohm) 2 way programmable alarm output (Dry contact type, maximum load 220VAC/2A) |

Other interface | RS232 (default) or RS485(optional), Ethernet |

Power supply | AC100 ~ 240V 50/60Hz, power consumption is less than 60VA |

Environment humidity | <80%RH |

Sample gas temperature | -10 ~ +60℃ |

Sample gas flow | 2 ~ 2.5l/min |

Sample gas pressure | micro-positive pressure, micro-negative pressure or normal pressure |

Sampling mode | extraction way |

Background gas | N2 and inactive gaseous mixture |

Appearance size | 180mm×266mm×305mm(H×W×D) |

Install hole cut | 182mm×231mm(H×W), In the case of embedded installation |

Air source pressure | 0.4 ~ 0.8MPa(PV inlet) |

Sampling circuit port | NPT 1/8 internal thread |

Controlling circuit port | NPT3/8 internal thread (PV connector) |

Flow range | 0 ~ 65m3/h(normal) |

Flow statistics range | 0~72m3/h (including cumulative flow function) |

Protection valve flow | 30~60m3/h (air source pressure 4~8bar) |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will improve and modify any information on the website from time to time without prior notice.